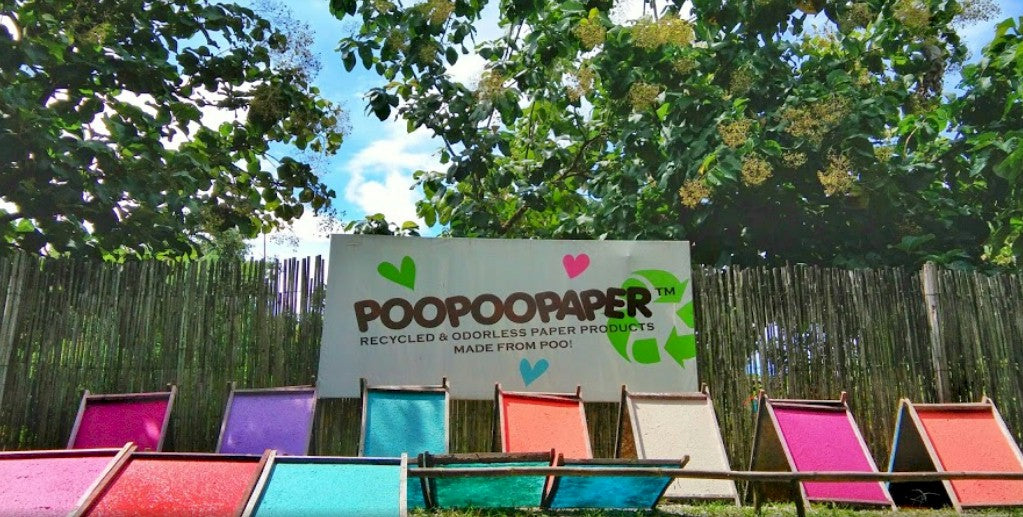

Discover Our Handmade Paper: Learn About The Poop To Paper Process

Share

When it comes to our handmade paper, we believe in turning waste into something wonderful—quite literally. Our paper products are crafted from recycled fibers from animal dung, offering an eco-friendly, sustainable alternative to conventional paper. The fibers in animal dung, particularly from herbivores like elephants and cows, make the perfect base for our unique, eco-friendly paper products. Beyond the environmental benefits, this process results in functional, artistic paper made by local artisans that is perfect for a variety of uses, from stationery to art projects. By choosing our recycled paper, you’re not only making a sustainable choice but also contributing to a creative and resourceful way of reducing waste.

The History of Handmade Paper

The idea of using animal dung to make handmade paper isn’t as unusual as it might sound. In fact, this practice has roots in ancient cultures across the world. Many communities, especially in Southeast Asia and Africa, have long used animal waste in crafting paper. The fibers found in dung are rich and sturdy, making them ideal for durable eco-friendly products. The use of dung in crafting holds cultural significance, representing resourcefulness and sustainability, which is a tradition we proudly continue with POOPOOPAPER™.

Our Poop to Handmade Paper Process

Many people have concerns when they first hear about paper made from dung. However, POOPOOPAPER™ is completely safe, hygienic, and odorless. The extensive cleaning and processing ensure that the final product is smooth, durable, and free from any unpleasant smells. Read on to learn more about our handmade paper process.

Step 1: Collection

It all starts with sourcing animal dung from ethical and sustainable farms and sanctuaries. In Particular, we get a lot of our elephant poo from the many sanctuaries in Chiang Mai, Thailand, where our handmade paper products are made. These animals are well-cared-for, and their waste is naturally collected, ensuring that no harm is done in the process. By working with local farms and conservation sanctuaries, we help support animal welfare and the surrounding local communities in Thailand.

Step 2: Cleaning and Preparation

Once the dung is collected, it’s thoroughly cleaned to ensure hygiene and safety. All non-fiber materials such as pebbles, dirt, mud, and leaves are removed as much as possible so that all that remains is actual fiber material. The fibers are then boiled for 4-6 hours which softens the fibers and makes them a slurry-like consistency for the paper-making process. This boiling process occurs at 90-100 degrees Celsius in order to ensure that the protein-based cells of any bacteria are destroyed by extreme heat.

Step 3: Pulping

After cleaning, the slurry-like product is then mixed with seasonally-available, non-wood fibers to give it extra strength and texture. These non-wood fibers may include corn stalks, pineapple husks, hay, banana tree trunks, mulberry bark and others depending on what’s available. This blending process further transforms the raw pulp into a stringy, cellulose-filled, stew mixture. It allows us to make a stronger, well bonded sheet of paper.

Once adequately mixed, we may even add our non-toxic, soy-based colorings to the off-white mixture to create dozens of different colors. At this point, the pulp is removed from the mixing reservoir and formed into round balls of similar weight. The water is drained from the mixing reservoir and can be used again for the next batch or used to water surrounding vegetation.

Step 4: Forming Sheets

The next step in this process is called Screening. The pulp is then carefully spread into molds to form paper sheets on a framed screen by our local craftspeople. This process requires precision and artistry, ensuring that each sheet is consistent in quality and thickness. This paper-making method dates back to the innovation of paper in China in 105 AD. We take pride in the craftsmanship involved, and this is where our artisans bring the handmade paper to life.

Step 5: Drying and Finishing

Once the pulp is carefully spread out on the framed screen, the sheets are laid out to dry in the sun. Once dry, the handmade paper is ready for finishing touches. This usually always involves cutting the paper into all sorts of shapes and sizes, gluing, binding and decorating and often printing. The result is a beautifully crafted, sustainable product that’s ready for use. Our innovative POOPOOPAPER™ are made into a wide variety of eco products, from ecofriendly journals and sustainable scratch pads to funny or heartwarming greeting cards.

Give Our Handmade Paper from Recycled Animal Waste A Try!

Our poop-to-paper process is a remarkable example of how innovation can meet sustainability. By choosing POOPOOPAPER™, you’re helping to reduce waste, conserve trees, and support sustainable practices that benefit both the environment and local communities. Each sheet of handmade paper is unique, making every product one-of-a-kind. Make a sustainable choice today and explore the world of handmade elephant poop paper with us.