Poop to Paper

The POOPOOPAPER Paper Making Process

From POOP to POOPOOPAPER™

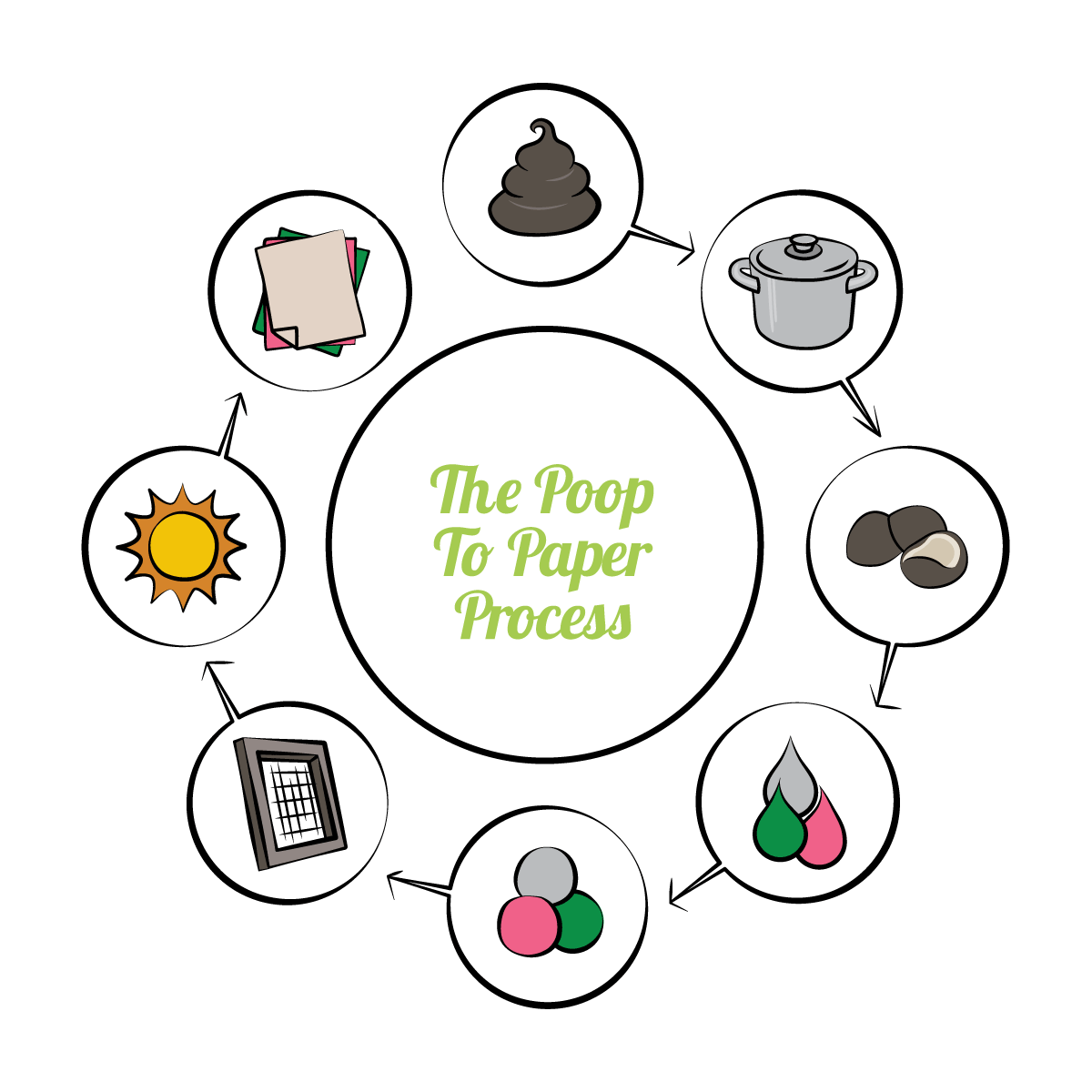

We love to introduce people to our paper and to teach them about the six steps that we use to make what we like to believe is a very beautiful, eco-friendly, organic, sustainable, tree-free POOPOOPAPERTM. Explore and learn about each of the steps in what we call our Poop-to-Paper Process.

- Collecting the Poo

- Cleaning and Boiling

- Mixing and Blending

- Coloring

- Screening

- Drying

Collecting

Elephant poo fibers are collected from some of the many elephant sanctuaries and parks in northern Thailand and our local mahout network. Poop fibers from other animals such as cows, horses, Thai buffalos, donkeys etc. come to us from many farms, dairies and stables in the region. All these materials are abundant locally and in many cases our removal of the waste material helpful and welcome.

Cleaning

Cleaning and boiling are important stages in the POOPOOPAPER papermaking process. All non-fiber materials such as pebbles, dirt, mud, leaves etc. are removed as much as possible at this point so that all that remains is actual fiber material. The fibers are then ‘boiled to a pulp’ for 4-6 hours which softens the fibers and makes them more supple resulting in an oatmeal-like slurry. The boiling process occurs at 90-100 degrees celsius in order to ensure that the protein based cells of any bacteria are destroyed by extreme heat. Our cleaning and boiling processes use no chemicals or other cleansing agents like bleach or chlorine that would be harmful to the environment – only water. Therefore, after cleaning and boiling the fibers the waste water can be re-used to boil more fibers or used to nourish our trees, flowers and gardens adjacent to our production.

Mixing

The next step is to thoroughly mix and blend the poo pulp fibers together with other seasonally available non-wood fiber pulp material which allows us to make a stronger, well bonded sheet of paper. These non-wood fibers may include corn stalks, pineapple husks, hay, banana tree trunks, mulberry bark and others depending on seasonal availability. The mixing and blending process further transforms the raw pulp into a stringy, cellulose-filled, stew mixture.

Once adequately mixed and blended, coloring may be added to the off-white mixture. Our process uses non-toxic food coloring to achieve dozens of different colors. At this point, the pulp is removed from the mixing reservoir and formed into round balls of similar weight. The water is drained from the mixing reservoir and can be used again for the next batch or used to water surrounding vegetation.

Screening

Screening refers to the process of making the actual sheets of paper using a framed screen. This method has not changed significantly since the innovation of paper in China in 105 AD.

- The pulp mixture is poured into a large sink or a basin filled with water where a framed screen is already submerged.

- The papermaker catches the sinking pulp fibers with the framed screen and then manually spreads the fibers evenly across the entire surface of the screen.

- Once the fibers are evenly spread and any small particles are removed by hand, the screen is lifted out of the basin, the water drips down through the screen and the screen is placed upright into the sunlight to dry naturally.

Drying

The screens lay facing the sun for several hours until the pulp has dried. The amount of time may vary depending on the weather and the thickness of the sheet being made. Once dry, the newly formed sheet is then easily removed from the screen. With a supply of freshly made sheets of POOPOOPAPER removed from the screens, the next step in the process is to prepare all the materials needed to make a POOPOOPAPER product. This usually always involves cutting the paper into all sorts of shapes and sizes, gluing, binding and decorating and often printing. POOPOOPAPER products are made into a wide variety of products, from journals and notepads to photo albums and greeting cards, the number of product components we have is large. Look and see what our artisans are crafting today on the tables in this pavilion and view the different parts and materials that are used to make a single item.

Products

POOPOOPAPER is made both by hand and by machine. Our handmade papers typically have a highly textured and rough surface. Smoother sheets can be attained by extending the boiling period of the pulp and by finely blending the pulp mixture prior to the screening stage. Our machine-milled papers are milled on a Fourdrinier style papermaking production line and typically result in a far more smooth and refined looking sheet of paper. The process is basically the same as the handmade process but automated. The variations between our different grades of paper are easily noticeable.

FEATURED POOPOOPAPER PRODUCTS

Check out some of our head-turningly beautiful, practical, tree-free, eco-friendly and sustainable gift and paper products made from poop!

-

Hearts 001 by POOPOOPAPER - Eco-friendly Scratch Pads (Set of 3)

Regular price $25.00 USDRegular priceUnit price / per -

Hearts 002 by POOPOOPAPER - Eco-friendly Scratch Pads (Set of 3)

Regular price $25.00 USDRegular priceUnit price / per -

Classic Elephant POOPOOPAPER - Two-Toned Blue - Eco-friendly Journal

Regular price $22.00 USDRegular priceUnit price / per -

Eco-friendly Greeting Card Elephant Mom & Baby - Assorted (Set of 5)

Regular price $25.00 USDRegular priceUnit price / per

FREE GLOBAL SHIPPING

on all orders over $50.